Reverse Engineering Methods

Reverse Engineering Service

Our reverse engineering service, which creates CAD models of damaged or worn parts by extracting the design intent, has 3 stages.

1. 3D Scanning: A series of 3D scanning technologies are used to capture millions of points that define the geometric features of the object. The raw raster data is called a "Point Cloud" which can be used to get dimensions. This data cloud is used in quality control work or as a guide for building a CAD model.

2. Creating a Mesh Model: The next step is to create a mesh model, unless the project requires the model to be created from the point cloud. A mesh model is created by joining the points forming triangular surfaces. Like a point cloud, the mesh model can be used for inspection or dimensioning. It is the mesh pattern that is normally used as a guide for creating a CAD model. Features such as embossed text and even notches can be removed from the mesh, and underlying geometry can be extracted to be used as a guide to speed up the modeling process.

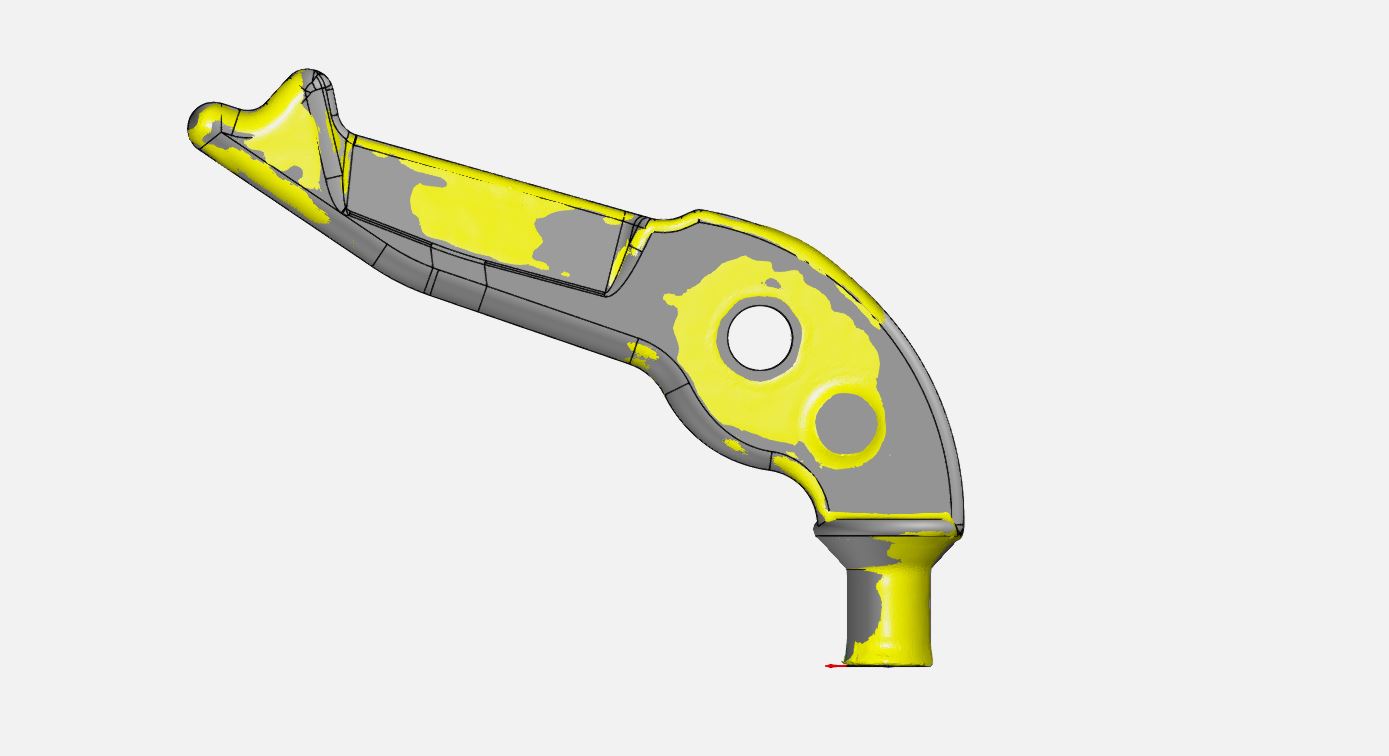

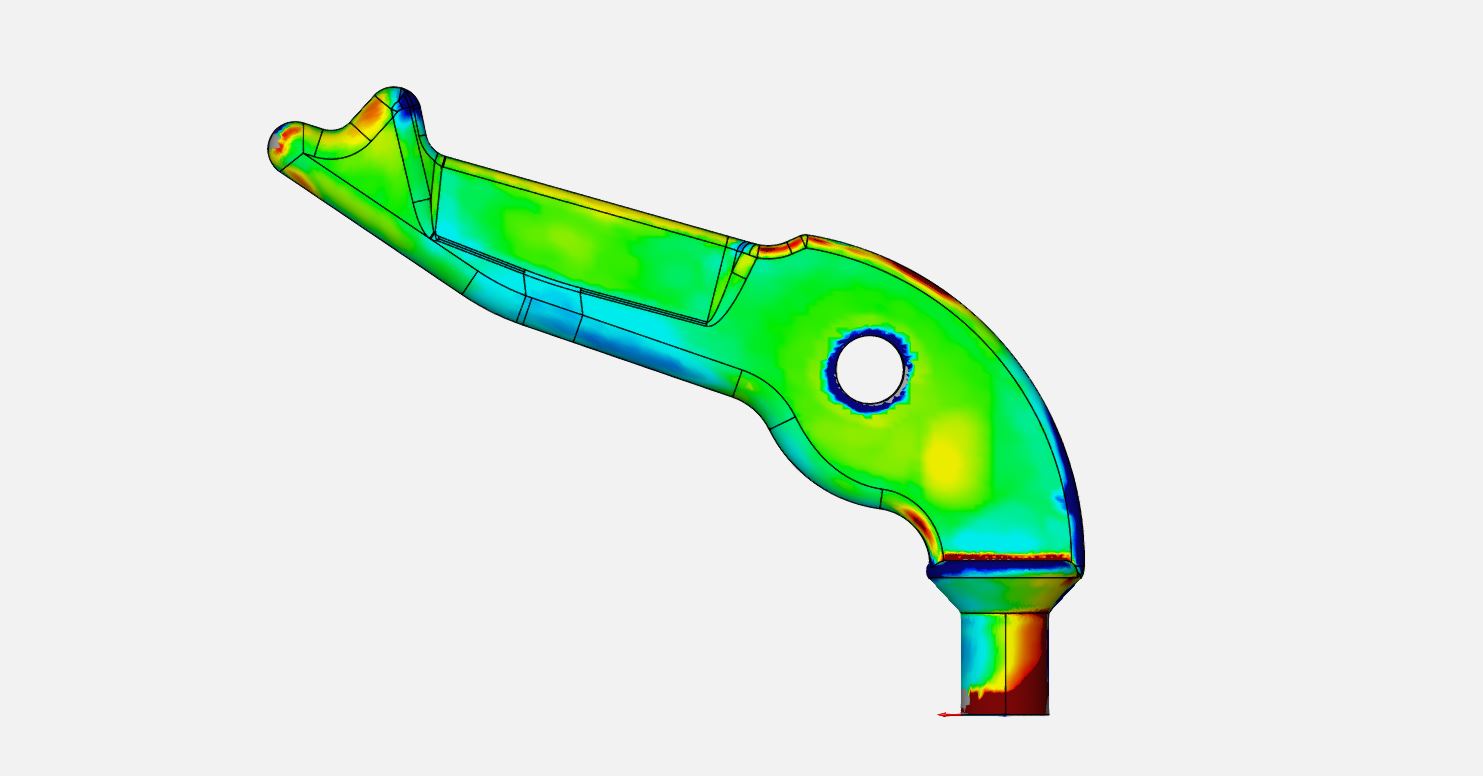

3. CAD Model Creation: Using the mesh or point cloud as a guide, the CAD model is created. The accuracy of the CAD model is checked against the initial scan data, which provides an accurate representation of the part. At this stage of creating a CAD model from the mesh, any damage or defect that could affect the actual part is removed or the design can be modified according to the customer's demands. If the customer also does not want any changes to the part, the CAD model can also be used as it is created.

Reverse Engineering Applications

Reverse engineering applications are used in different industries to meet different needs. What can RE applications be?